PLC vs. DCS Programming

Are you interested in learning about the world of industrial automation and control systems? In this blog post, we will delve into the fascinating realm of PLC (Programmable Logic Controller) and DCS (Distributed Control System) programming. We will start with an introduction to PLC programming, exploring its basics and fundamental concepts. Then, we will move on to DCS programming, providing an overview of its functionality and key elements. Additionally, we will compare PLC and DCS systems, highlighting their differences and applications. Moreover, we will discuss the various programming languages used for PLC and DCS, along with the pros and cons of each system. Whether you’re a newbie or industry professional, this post will offer valuable insights into the world of PLC and DCS programming. So, let’s dive in!

Plc Programming: Introduction And Basics

Programmable Logic Controller (PLC) programming is a crucial part of automation in industries. It is a specialized computer used for the control of manufacturing processes such as assembly lines, robotic devices, and more. PLCs are designed to withstand harsh industrial environments and are favored for their reliability and durability.

PLC programming involves creating and implementing logic using specialized software. This logic is used to dictate the operation of the machinery controlled by the PLC. The programming language used for PLCs is typically ladder logic, a graphical programming language that represents the control circuits in the form of relay logic.

One of the fundamental aspects of PLC programming is understanding the input and output signals that the PLC will be dealing with. These inputs and outputs are connected to sensors, actuators, and other devices and play a crucial role in the control and monitoring of industrial processes.

Dcs Programming: Overview And Fundamentals

DCS Programming: Overview And Fundamentals

DCS, or Distributed Control System, programming is a crucial aspect of modern industrial automation. It involves the use of specialized software to create and manage the control algorithms that govern the behavior of industrial processes. DCS programming is essential for ensuring that all the components of a plant work together seamlessly to achieve the desired production targets. In this blog post, we will take a closer look at the overview and fundamentals of DCS programming.

One of the key differences between DCS and PLC programming is that DCS systems are designed to control large, complex processes that require coordination between multiple control loops and subsystems. This makes DCS programming more focused on process-oriented control, as opposed to the discrete control typically associated with PLCs. DCS programming also typically involves the use of advanced control strategies such as cascade control, feedforward control, and model-based control, which are essential for optimizing the performance of complex industrial processes.

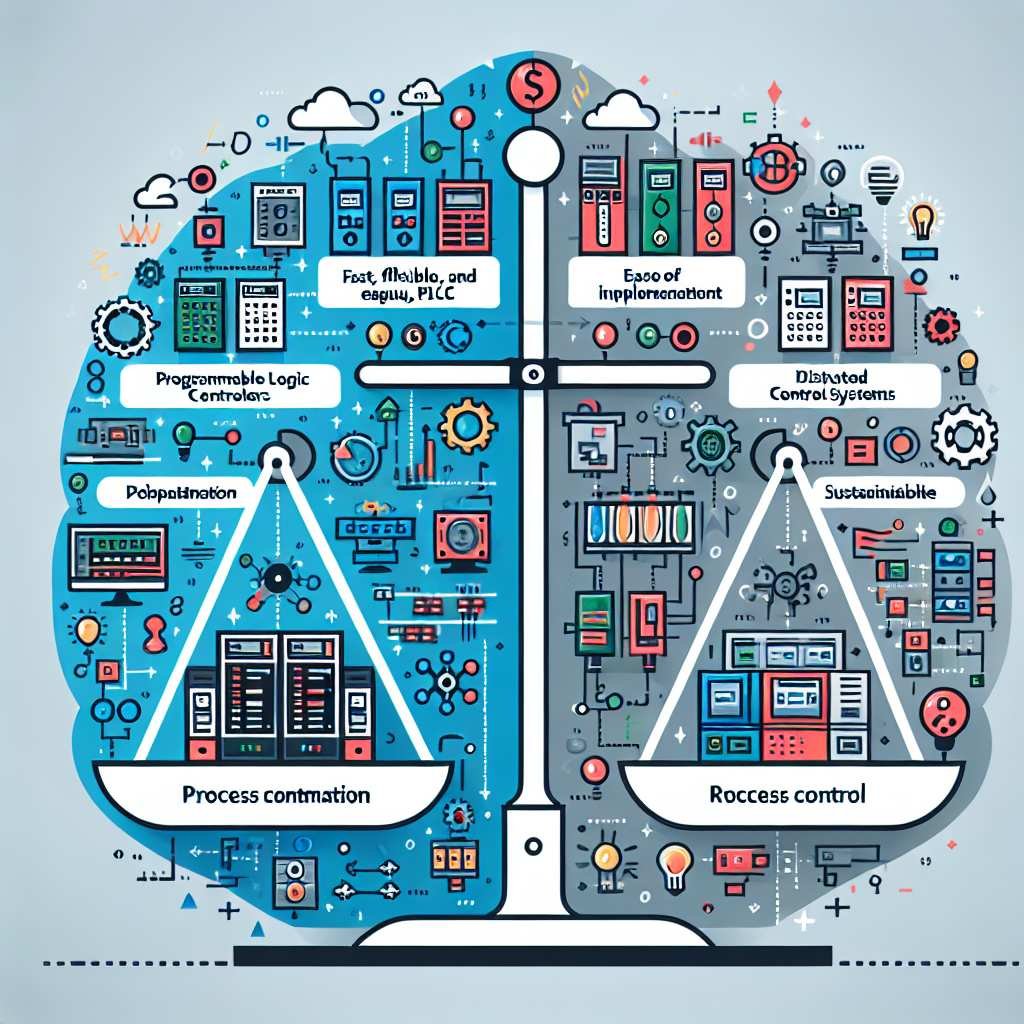

Plc Vs. Dcs: Key Differences And Applications

When it comes to industrial automation, both PLCs (Programmable Logic Controllers) and DCSs (Distributed Control Systems) play a critical role. However, there are key differences between the two, as well as specific applications where each is better suited. Understanding these differences and applications is essential for anyone working in the field of industrial automation.

One of the primary differences between PLCs and DCSs lies in their architecture. PLCs are designed for discrete control applications, such as assembly lines and packaging machines. They have a simple and rugged design, making them well-suited for harsh industrial environments. In contrast, DCSs are designed for continuous control processes, such as chemical plants and power generation facilities. They feature a distributed architecture, allowing them to control multiple processes across a large area.

Another key difference between PLCs and DCSs is their programming. PLCs are typically programmed using ladder logic, which is a graphical programming language that is easy to understand for those familiar with electrical circuit diagrams. On the other hand, DCSs are often programmed using function block diagrams or sequential function charts, which are more suitable for complex control strategies needed in continuous processes.

Programming Languages For Plc And Dcs

When it comes to PLC and DCS programming, understanding the different programming languages is essential for success in the field. The programming language used in a PLC (Programmable Logic Controller) or DCS (Distributed Control System) can vary depending on the specific application and requirements. Each programming language has its own unique syntax and features, making it important for PLC and DCS programmers to have a solid understanding of the available options.

Some of the most common programming languages for PLC and DCS include ladder logic, function block diagram (FBD), structured text (ST), and sequential function chart (SFC). Ladder logic is often used for PLC programming, as it resembles electrical relay circuits and is easy to understand for those with a background in electrical engineering. On the other hand, function block diagram (FBD) is a graphical language that represents the functions of a PLC or DCS system using a series of interconnected blocks.

Structured text (ST) is a high-level programming language that is similar to Pascal and is often used for complex PLC and DCS applications. Finally, sequential function chart (SFC) is a graphical programming language that represents the steps and transitions of a process in a PLC or DCS system. Understanding these programming languages is crucial for PLC and DCS programmers to effectively design, implement, and troubleshoot automation systems.

Pros And Cons Of Plc And Dcs Programming

One of the major decisions that engineers and system integrators face when designing automation systems is whether to use PLC (Programmable Logic Controller) or DCS (Distributed Control System) for their programming needs. Both have their own advantages and disadvantages, and it is important to consider these factors before making a decision.

One of the major pros of using PLC programming is its flexibility. PLCs can be easily reprogrammed and modified to accommodate changes in the production process, making them ideal for industries with rapidly evolving requirements. On the other hand, one of the cons of PLC programming is that it can become complex and cumbersome to manage in large-scale systems, and the programming language can be less standardized compared to DCS.

When it comes to DCS programming, one of the major pros is its ability to handle large-scale industrial processes with ease. DCS offers centralized control and monitoring of numerous devices and processes, making it suitable for industries with extensive automation needs. However, one of the cons of DCS programming is that it may not be as suitable for applications that require frequent modifications or have a smaller scale, as the setup and programming can be time-consuming and less flexible compared to PLCs.