The Impact of PLC in the Oil and Gas Industry: Upstream and Downstream Applications

The use of Programmable Logic Controllers (PLC) has greatly transformed the operations within the oil and gas industry, both upstream and downstream. PLC technology has significantly enhanced exploration and production processes, optimized well operations, improved safety and environmental compliance, streamlined refining and petrochemical processes, and maximized efficiency in transportation and storage. In this blog post, we will explore the impact of PLC in the oil and gas industry, delving into the various applications and benefits it offers. From its role in enhancing the exploration and production of oil and gas reserves to its contribution to the safety and environmental compliance of refineries and petrochemical plants, PLC technology has become integral to the industry’s operations. Additionally, we will also discuss the future trends and innovations in PLC for the oil and gas industry, providing insights into the potential advancements that could further revolutionize the sector. Join us as we delve into the intricate world of PLC in the oil and gas industry.

Introduction to PLC in the Oil and Gas Industry

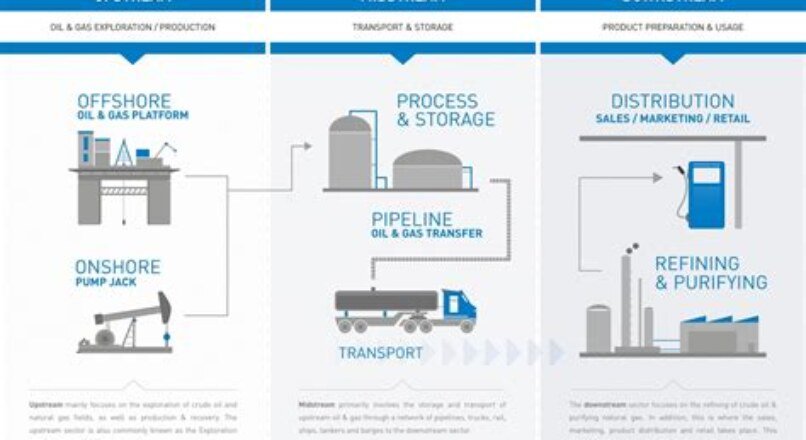

Programmable Logic Controllers (PLC) play a crucial role in the oil and gas industry, serving as the backbone of automation and control systems. These electronic devices are used to monitor and manage various processes in the exploration, production, refining, and transportation of oil and gas.

PLCs are designed to withstand harsh operating conditions, making them suitable for use in offshore platforms, pipelines, and refineries. They are programmed to execute specific tasks, such as opening and closing valves, regulating pressure and temperature, and managing equipment operation.

With the increasing complexity of oil and gas operations, the use of PLCs has become indispensable. They have revolutionized the industry by providing real-time monitoring, data acquisition, and control capabilities, leading to improved efficiency, safety, and productivity.

As technology continues to advance, PLCs are expected to play an even greater role in the future of the oil and gas industry, driving innovations in automation, data analytics, and remote operation. Their versatility and reliability make them an essential component in achieving sustainable and cost-effective production processes.

Enhancing Exploration and Production Processes

Exploration and production processes in the oil and gas industry are crucial for discovering and extracting valuable resources from the earth’s crust. With the advancement in technology, Programmable Logic Controllers (PLCs) have played a significant role in enhancing these processes.

PLCs have revolutionized the way exploration and production activities are carried out, allowing for more efficient and precise control over the various operations involved. From drilling to well completion, PLCs have helped to streamline and automate many of the tasks involved, reducing the need for manual intervention and increasing overall productivity.

Furthermore, the integration of PLCs in exploration and production processes has also led to improved safety measures. By providing real-time monitoring and control of equipment and processes, PLCs help to mitigate potential risks and hazards, ensuring a safer working environment for workers on-site.

In addition, PLCs have also contributed to the optimization of resource utilization, leading to cost savings and improved sustainability in exploration and production activities. With the ability to regulate and manage energy consumption, equipment usage, and production output, PLCs have become an essential tool for the efficient operation of oil and gas facilities.

Optimizing Well Operations with PLC

Optimizing Well Operations in the oil and gas industry is crucial for improving efficiency and productivity. With the advancement of technology, PLC (Programmable Logic Controller) has become an essential tool for enhancing the performance of well operations. By utilizing PLC systems, oil and gas companies can streamline their processes, automate tasks, and minimize downtime, ultimately leading to cost savings and improved output.

One of the key benefits of implementing PLC in well operations is the ability to monitor and control various parameters in real time. This allows operators to make quick adjustments and optimize the performance of pumps, valves, and other equipment. By having a centralized control system, companies can ensure that their wells are operating at peak efficiency, leading to increased production and reduced operational costs.

In addition, PLC systems can help in predictive maintenance by monitoring the condition of equipment and detecting potential issues before they escalate. This proactive approach to maintenance minimizes the risk of unexpected breakdowns and downtime, resulting in improved reliability and operational continuity.

Furthermore, the integration of PLC with data analytics and machine learning enables companies to gain valuable insights into their well operations. By analyzing the data collected from PLC systems, companies can identify opportunities for optimization, identify trends, and make informed decisions to further enhance their operations.

Improving Safety and Environmental Compliance

In the oil and gas industry, safety and environmental compliance are of utmost importance. With the use of Programmable Logic Controllers (PLC), companies can significantly improve their safety protocols and ensure adherence to environmental regulations. PLC systems can be utilized to automate crucial safety functions, such as emergency shutdown systems and fire and gas detection, thus reducing the risk of accidents and ensuring a safer working environment for all personnel.

Furthermore, PLC technology can also be employed to monitor and control emissions, waste disposal, and other environmental compliance measures. By automating these processes, companies can minimize the potential for human error and ensure that they are operating in accordance with all environmental regulations and standards. This not only enhances the company’s environmental footprint but also mitigates the risk of potential fines or penalties for non-compliance.

Additionally, the use of PLC systems allows for real-time monitoring and analysis of safety and environmental data, providing valuable insights that can aid in the development of proactive measures to further improve safety and environmental practices. By leveraging PLC technology, companies can stay ahead of potential safety hazards and proactively address any environmental concerns, thereby demonstrating a commitment to responsible and sustainable operations.

In conclusion, the integration of PLC systems is instrumental in improving safety and ensuring environmental compliance within the oil and gas industry. By automating critical safety functions, monitoring emissions, and leveraging real-time data, companies can not only protect the well-being of their personnel but also contribute to a healthier and more sustainable environment.

Streamlining Refining and Petrochemical Processes

Refining and petrochemical processes play a crucial role in the oil and gas industry, as they are responsible for turning crude oil into valuable products such as gasoline, diesel, jet fuel, and various chemicals. Streamlining these processes is essential for increasing efficiency and reducing operational costs.

One way to streamline refining and petrochemical processes is by implementing Programmable Logic Controllers (PLCs) to automate various tasks such as temperature control, pressure regulation, and flow monitoring. By using PLCs, operators can optimize the production process, minimize downtime, and ensure consistent product quality.

Furthermore, integrating advanced supervisory control and data acquisition (SCADA) systems with PLCs enables real-time monitoring of refining and petrochemical operations. This allows operators to make informed decisions based on live data, identify potential issues, and take proactive measures to prevent costly equipment failures.

Moreover, utilizing predictive maintenance technologies in conjunction with PLCs can help anticipate equipment failures, schedule maintenance activities during planned shutdowns, and avoid unexpected operational disruptions. By adopting a proactive approach to maintenance, refining and petrochemical processes can operate more smoothly and efficiently.

Maximizing Efficiency in Transportation and Storage

Transportation and storage are critical aspects of the oil and gas industry, and implementing PLC technology can significantly improve efficiency in these areas. By utilizing PLC systems, companies can streamline their transportation processes, ensuring that products are delivered to their destinations in a timely manner. This not only reduces the likelihood of delays and disruptions but also ultimately leads to cost savings for the company.

Furthermore, PLC technology can be applied to storage facilities to efficiently monitor and control inventory levels, prevent costly overfilling or stock shortages, and ensure the safety of both the product and the workers. This level of automation can help minimize human error and improve overall operational efficiency.

Another benefit of PLC in transportation and storage is the ability to track and trace products as they move through the supply chain. This enables companies to optimize their logistics, avoid unnecessary transport, and reduce the risk of product loss or theft.

In conclusion, integrating PLC technology in transportation and storage operations is crucial for companies in the oil and gas industry to maximize efficiency, minimize costs, and ensure the seamless movement of products from production to market.

Future Trends and Innovations in PLC for Oil and Gas

In the oil and gas industry, the future of Programmable Logic Controllers (PLC) is constantly evolving, with new trends and innovations shaping the way operations are managed and executed. As technology continues to advance, PLC systems are becoming more sophisticated and capable of handling complex tasks with greater efficiency and precision.

One of the key future trends in PLC for oil and gas is the integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms. These technologies are being used to analyze large volumes of data from sensors and equipment, allowing for predictive maintenance and real-time decision-making. This not only improves operational efficiency but also reduces downtime and maintenance costs.

Another innovation in PLC for oil and gas is the adoption of Industrial Internet of Things (IIoT) devices. These connected sensors and devices enable remote monitoring and control of equipment, as well as the collection of valuable operational data. This data can then be used to optimize processes and identify areas for improvement, leading to increased productivity and cost savings.

Furthermore, advancements in cybersecurity solutions are also a major focus for future PLC in the oil and gas industry. With the increasing threat of cyber-attacks, it is essential to implement robust security measures to protect critical infrastructure and data. This includes the use of encryption, authentication, and intrusion detection systems to safeguard PLC systems from potential threats.