Allen Bradley PLC Function Block Programming

| Introduction |

| Understanding Allen Bradley PLC and Function Block Programming |

| Benefits of Allen Bradley PLC Function Block Programming |

| Getting Started with Allen Bradley Function Block Programming |

| Creating Function Blocks |

| Configuring Inputs and Outputs |

| Programming Logic with Function Blocks |

| Best Practices for Efficient Function Block Programming |

| Real-World Applications |

| Troubleshooting Tips |

| Conclusion |

| FAQs |

In this article, we will explore Allen Bradley PLC function block programming and how it can be used to create efficient and modular control logic for industrial automation systems. Allen Bradley PLCs are widely used in the industry due to their reliability and versatility. By understanding and leveraging function block programming, you can enhance the control capabilities of your automation projects.

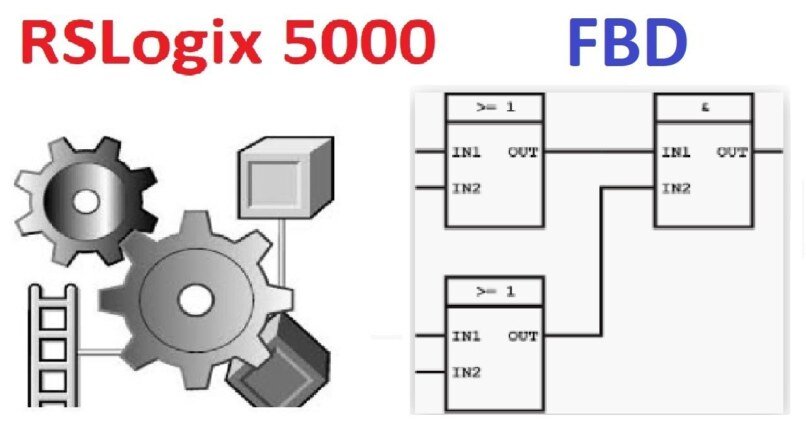

Understanding Allen Bradley PLC and Function Block Programming

Allen Bradley PLCs are programmable logic controllers manufactured by Rockwell Automation. These PLCs are known for their robustness and are used in various industries for automating processes. Function block programming is a powerful method used in Allen Bradley PLCs to create reusable and modular control logic.

Benefits of Allen Bradley PLC Function Block Programming

By utilizing function block programming in Allen Bradley PLCs, you can experience several benefits:

- Modularity: Function blocks allow you to encapsulate specific functionalities or control operations into reusable modules. This modularity simplifies code maintenance and promotes code reusability across different projects.

- Code Reusability: With function blocks, you can create libraries of pre-built blocks that can be easily integrated into new projects. This saves development time and ensures consistent and reliable control logic across multiple applications.

- Efficient Troubleshooting: Function block programming simplifies troubleshooting by isolating specific functionalities into separate blocks. This allows for easier identification and resolution of issues, enhancing the overall maintenance process.

- Scalability: Function blocks facilitate scalability as they can be easily duplicated and interconnected to handle larger and more complex automation systems. This scalability is crucial for adapting to changing requirements or expanding operations.

Getting Started with Allen Bradley Function Block Programming

Creating Function Blocks

To get started with function block programming, you need to define the necessary function blocks based on the control requirements of your automation system. Function blocks can represent various components such as motors, sensors, valves, or complex control operations.

Configuring Inputs and Outputs

Within each function block, you will define the required inputs and outputs. Inputs receive signals from external devices or other function blocks, while outputs provide control signals to actuators or other components. Properly configuring inputs and outputs is crucial for ensuring the correct operation of the function block.

Programming Logic with Function Blocks

In Allen Bradley function block programming, you will use ladder logic, structured text, or other supported programming languages to define the logic within each function block. The programming language you choose depends on your familiarity and the complexity of the control operations.

Within the function block logic, you will incorporate various instructions, comparisons, and control structures to define the behavior of the block. This includes handling different states, implementing timers or counters, and responding to specific input conditions.

Best Practices for Efficient Function Block Programming

To ensure efficient function block programming in Allen Bradley PLCs, consider the following best practices:

Structured Code Organization

Organize your function blocks and related code in a structured manner to enhance readability and maintainability. Use consistent naming conventions, group-related blocks, and provide appropriate comments to explain the purpose and functionality of each block.

Reusable Function Blocks

Design your function blocks with reusability in mind. Ensure that each block performs a specific and independent function, allowing it to be easily integrated into different projects. Avoid embedding specific application-related logic within the blocks to maintain their generality.

Documentation and Comments

Document your function block programming thoroughly. Provide clear and concise documentation for each function block, explaining its inputs, outputs, and internal operations. Additionally, add comments within the code to improve understandability and facilitate collaboration with other programmers or maintenance personnel.

Real-World Applications

Allen Bradley function block programming finds applications in various industrial automation scenarios, such as:

- Motor Control: Function blocks can be used to control the speed, direction, and positioning of motors in different applications.

- Process Control: Function blocks are beneficial for handling complex control operations in industries like chemical processing, oil and gas, or water treatment.

- Material Handling: Function blocks facilitate the control of conveyors, robotic arms, and other material-handling equipment in manufacturing and logistics industries.

Troubleshooting Tips

When troubleshooting Allen Bradley function block programs, consider the following tips:

- Online Monitoring: Utilize the online monitoring features provided by Allen Bradley software to observe the behavior of function blocks in real time. Monitor inputs, outputs, and internal variables to identify potential issues.

- Diagnostic Tools: Leverage the diagnostic tools offered by Allen Bradley software to analyze error codes, log files, or system status. These tools can provide valuable insights into the root causes of any malfunction or unexpected behavior.

- Simulation and Testing: Before deploying your function block program, simulate and test it in a virtual environment. This helps identify and rectify any programming errors or design flaws before they impact the live system.

Conclusion

Allen Bradley PLC function block programming provides a powerful method for creating modular and efficient control logic in industrial automation systems. By leveraging the benefits of function blocks, you can achieve code reusability, scalability, and efficient troubleshooting. Adhering to best practices and considering real-world applications will empower you to design and implement robust automation solutions using Allen Bradley PLCs.

FAQs

FAQ 1: What is function block programming in Allen Bradley PLCs?

FAQ 2: How does function block programming benefit automation projects?

FAQ 3: How can I get started with Allen Bradley function block programming?

FAQ 4: What are the best practices for efficient function block programming?

FAQ 5: What are the real-world applications of Allen Bradley function block programming?